location_on 4131 Fraser St. Vancouver BC Get Directions

phone 604-875-1993 Call us

access_time Hours

| Monday - Friday | 9AM - 5:30PM |

| Saturday - Sunday & Holidays | Closed | See Holiday Hours |

|

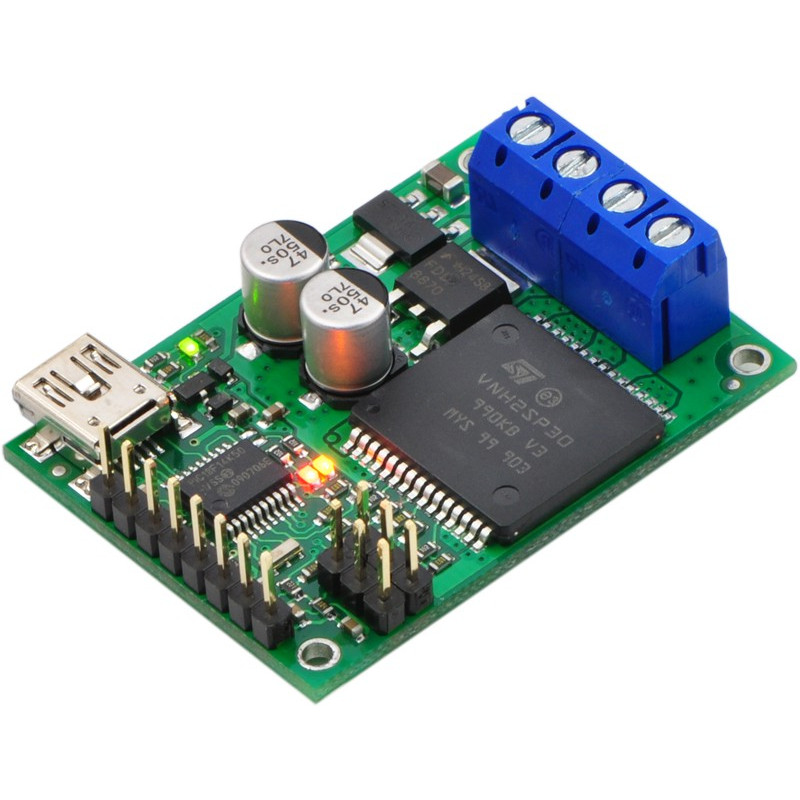

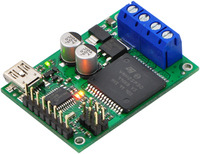

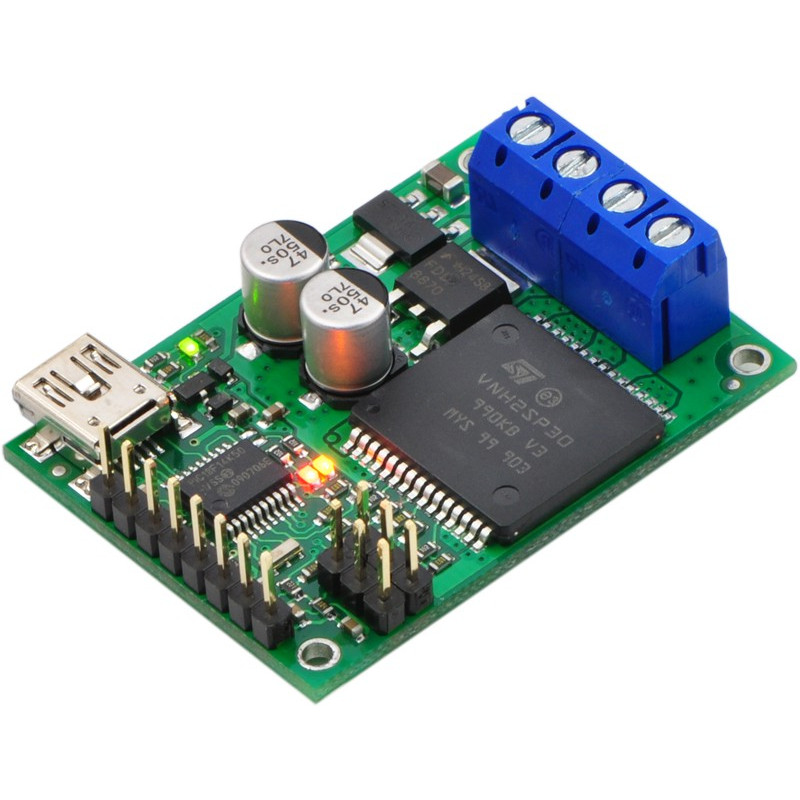

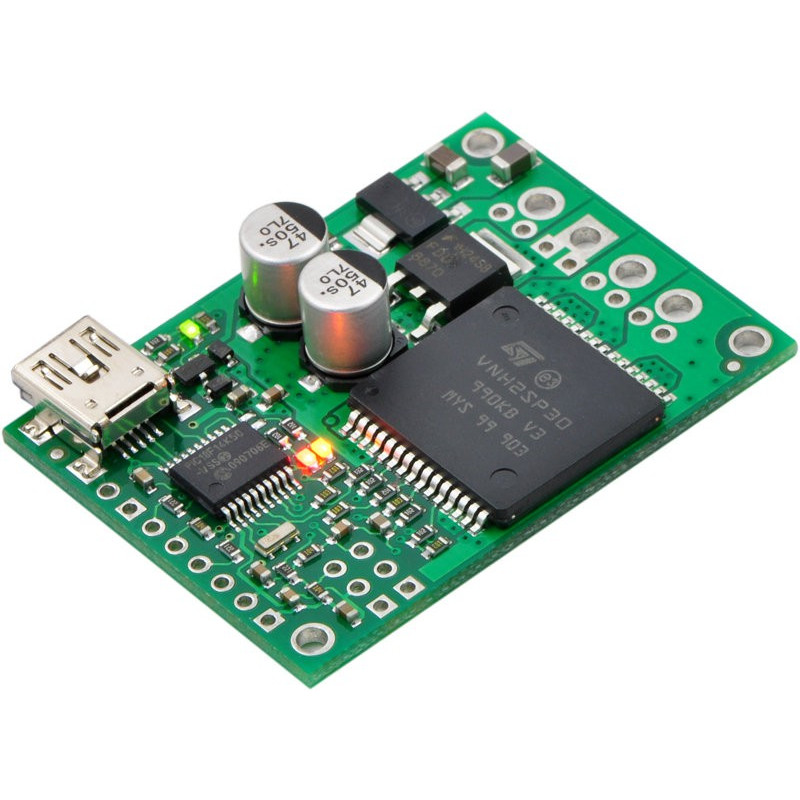

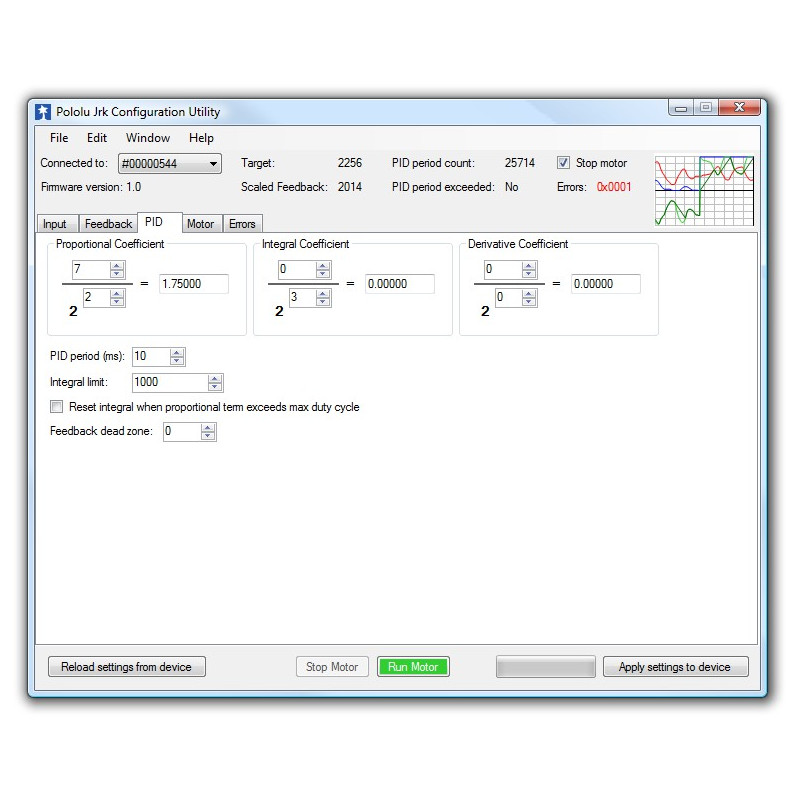

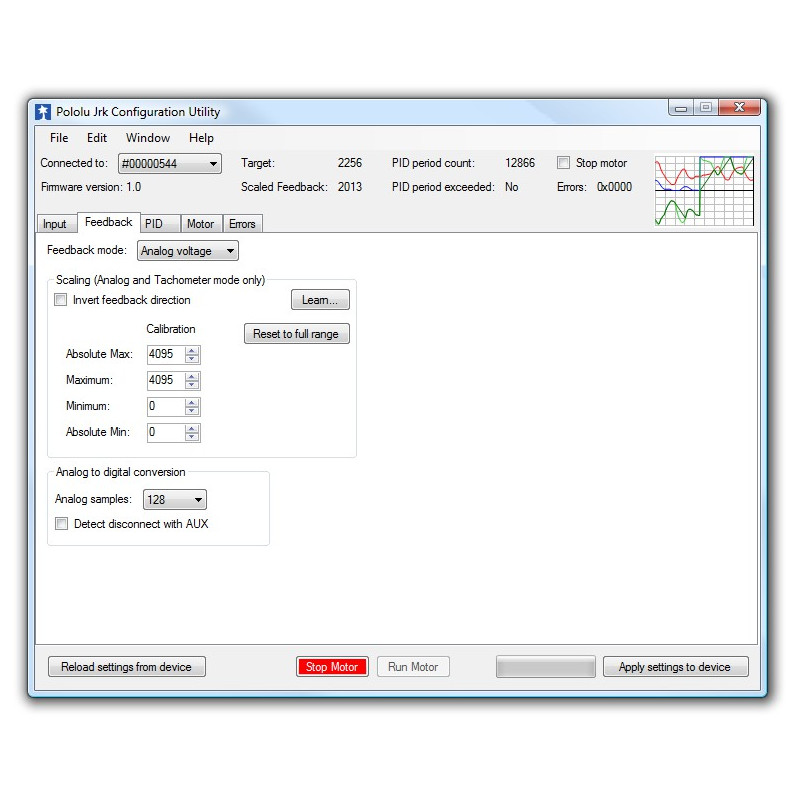

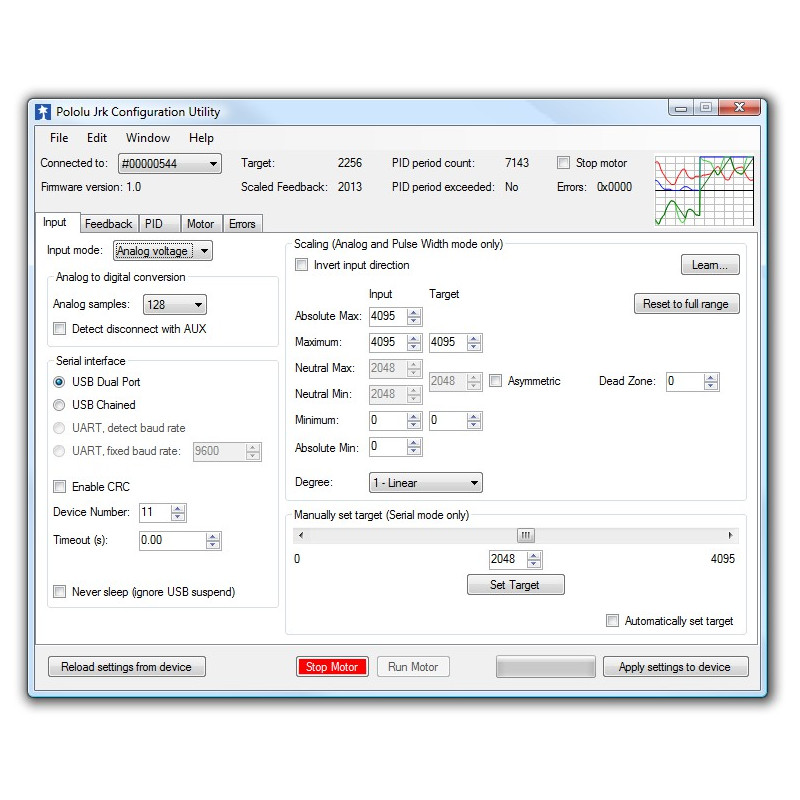

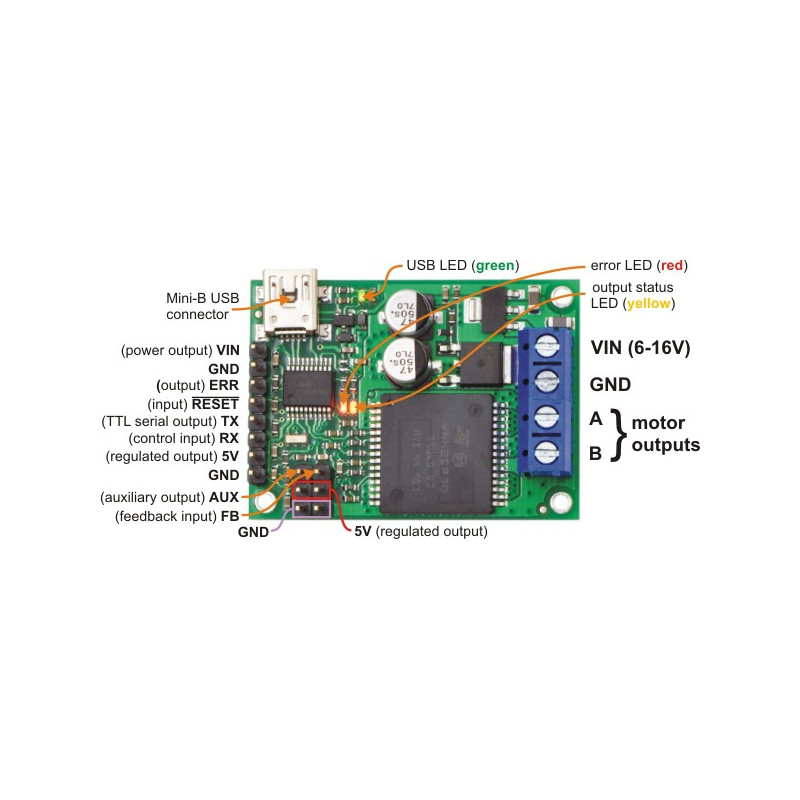

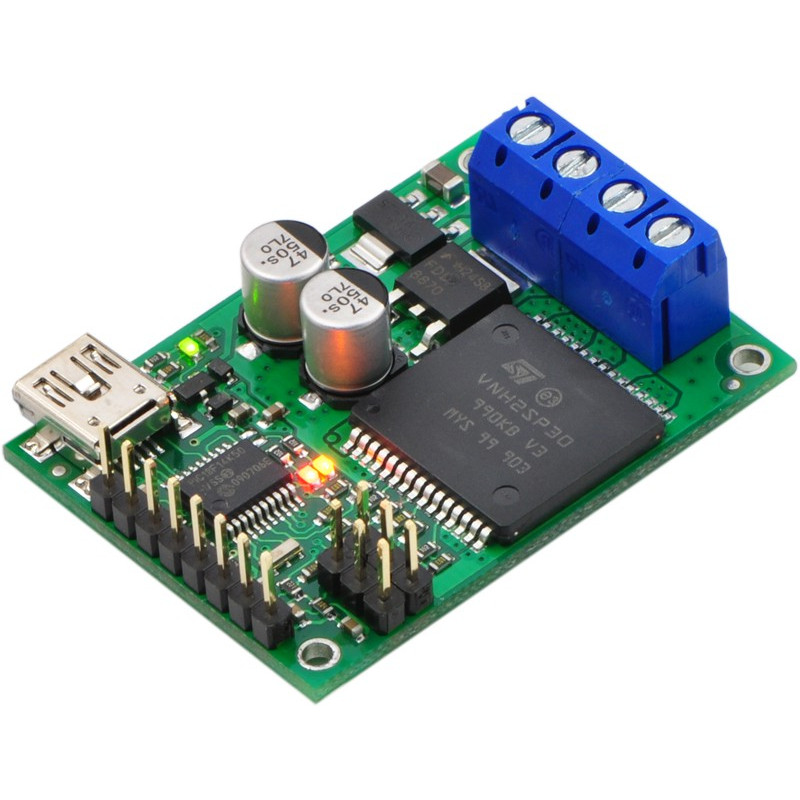

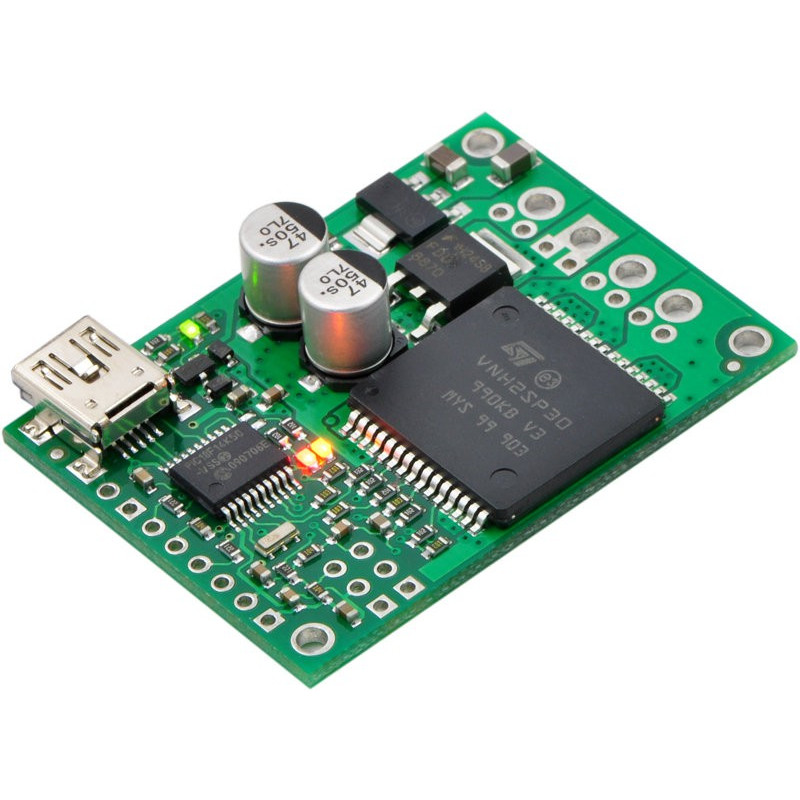

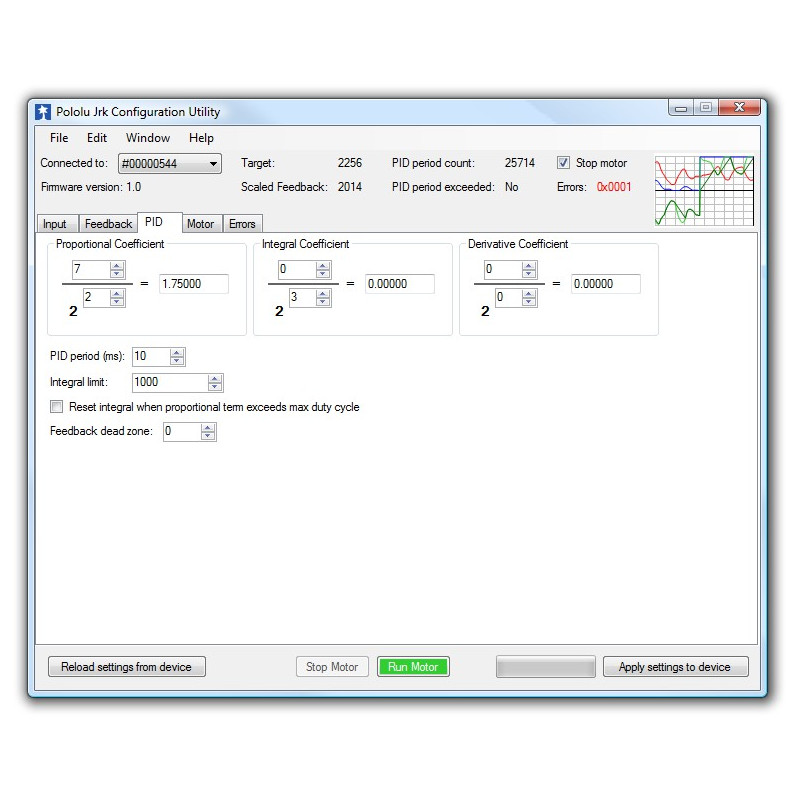

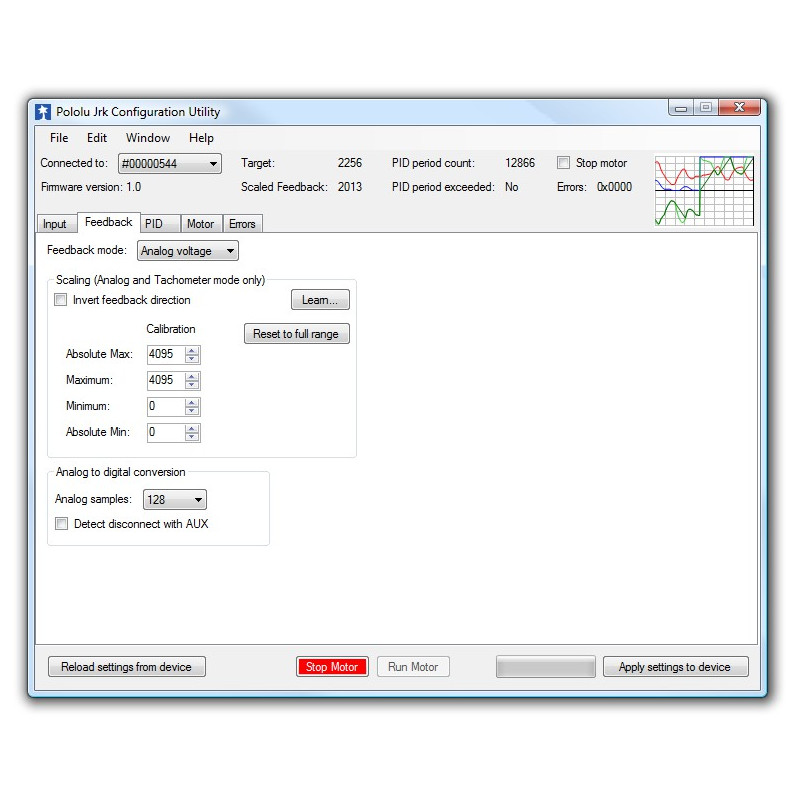

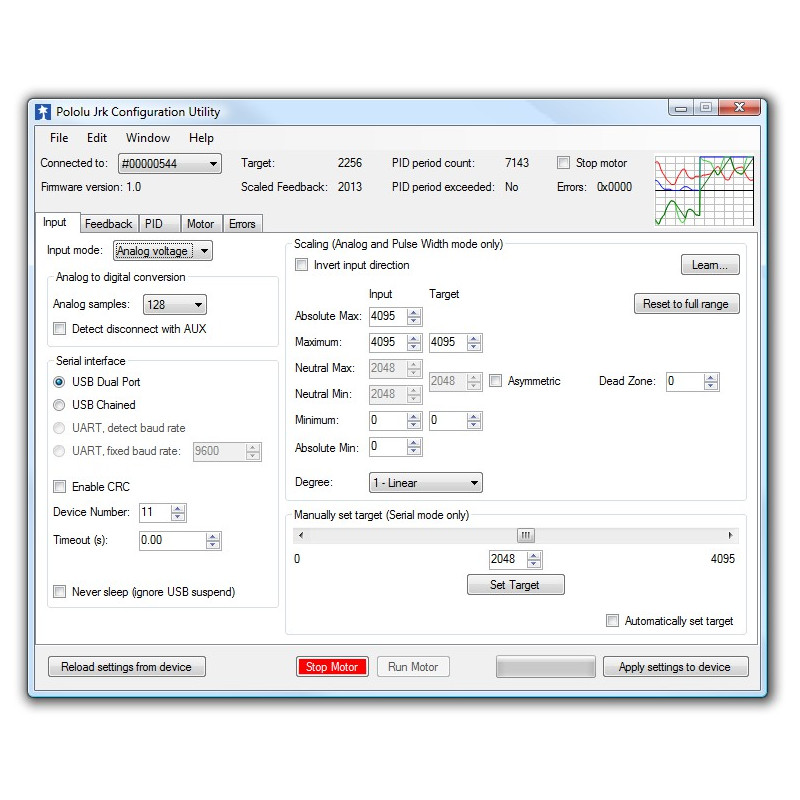

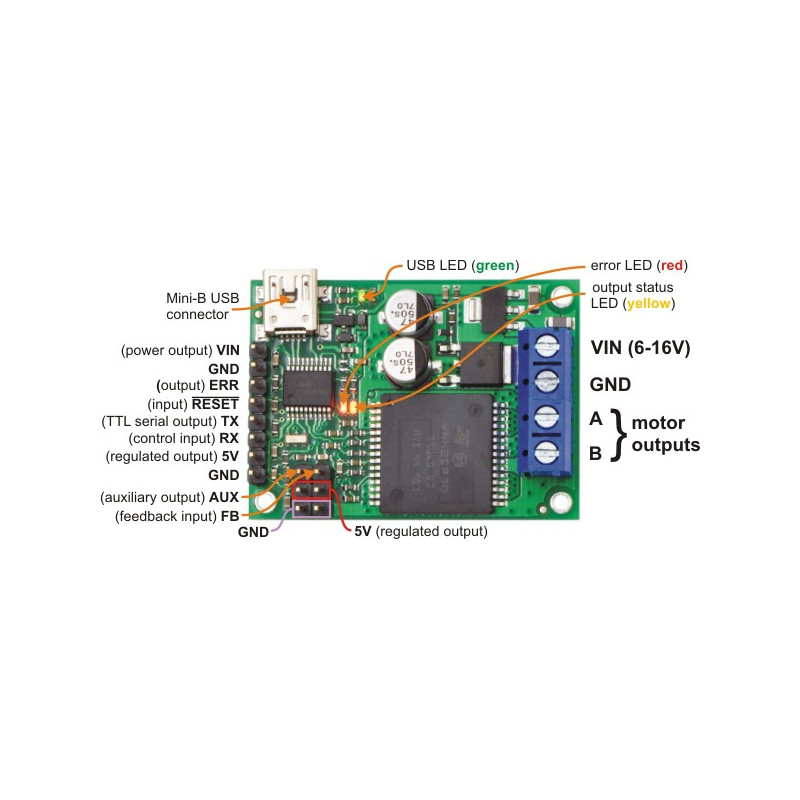

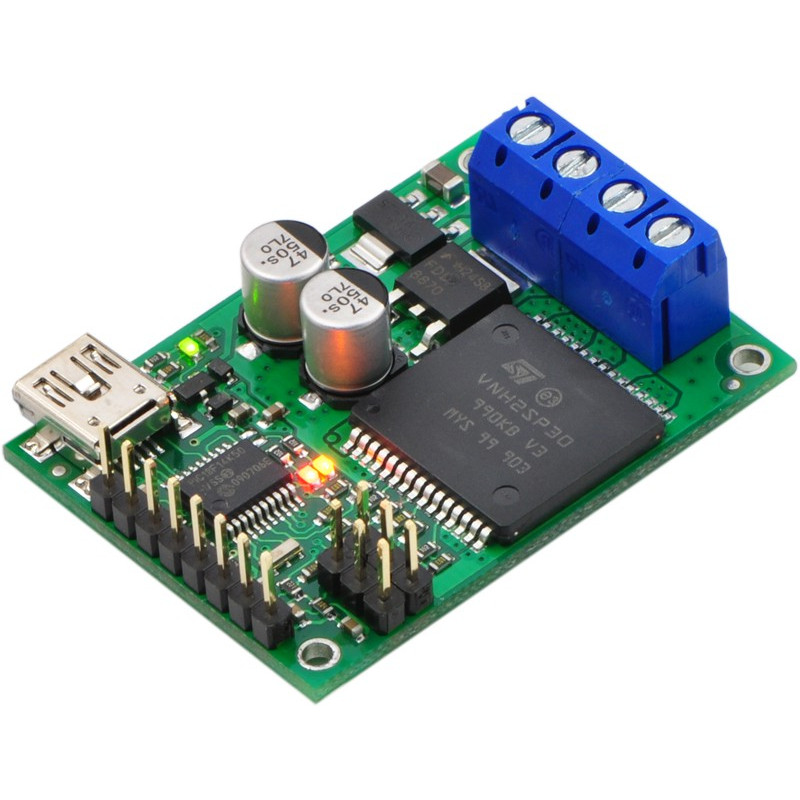

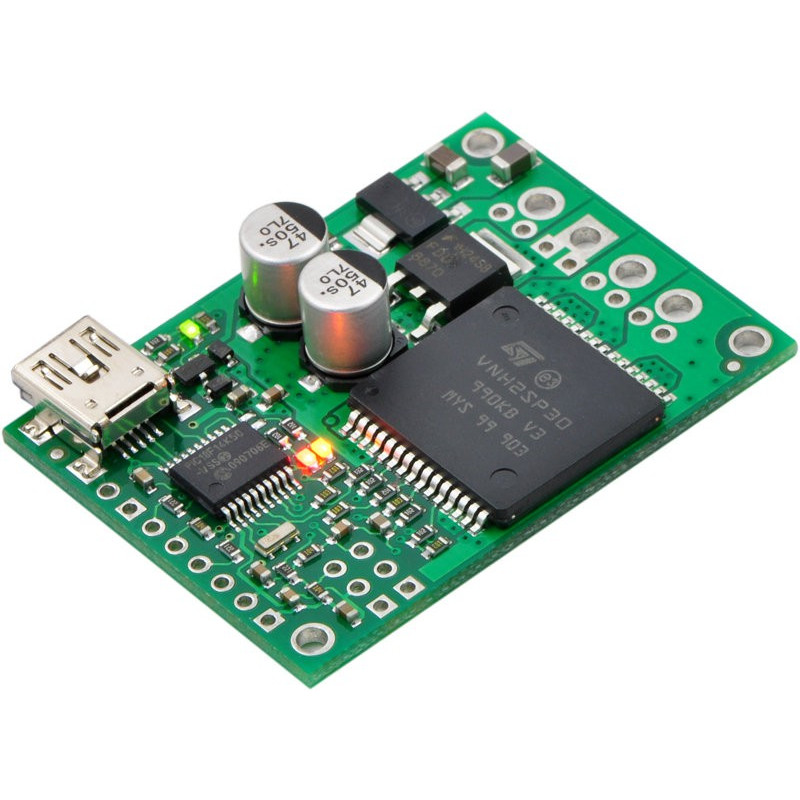

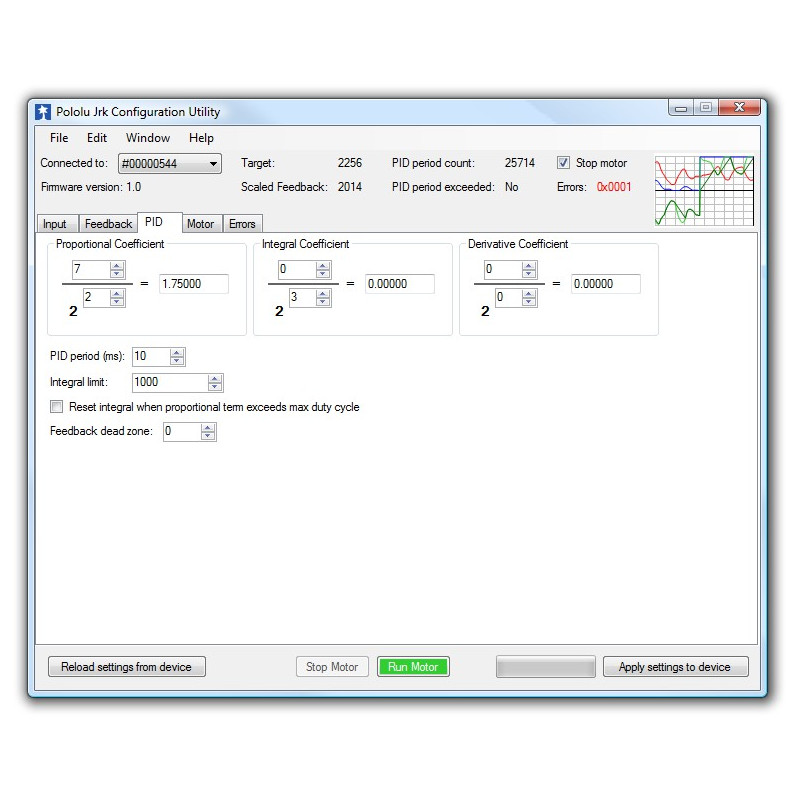

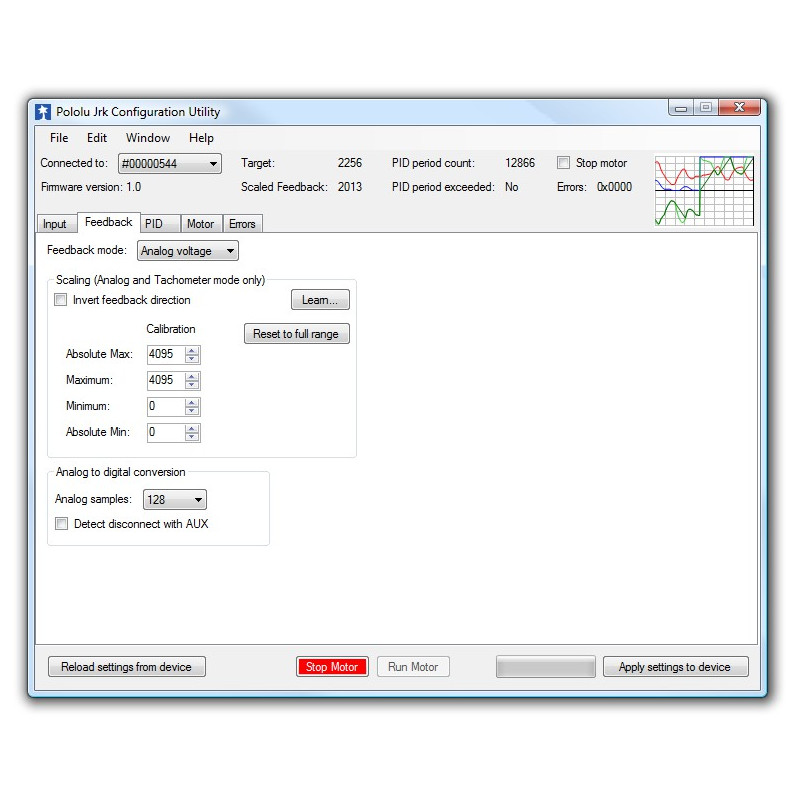

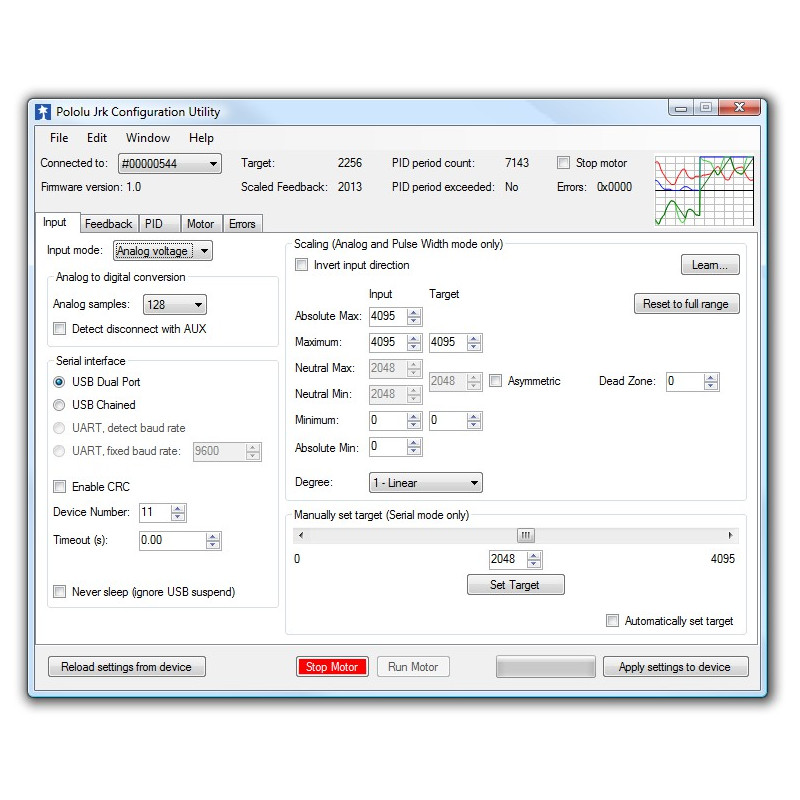

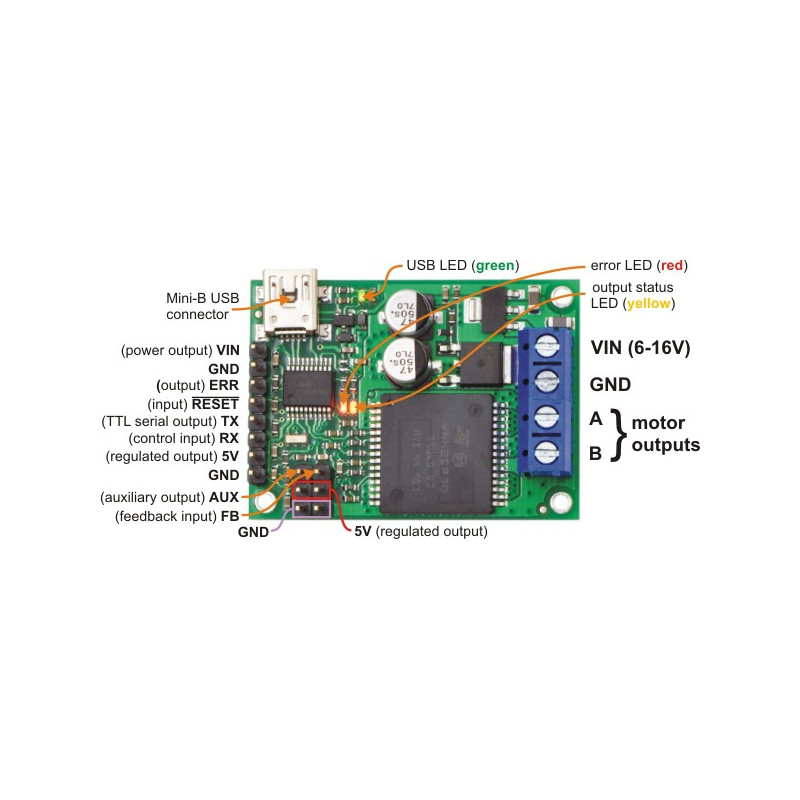

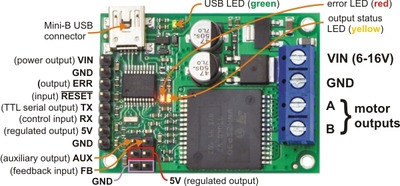

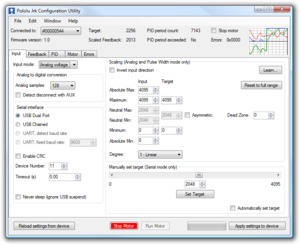

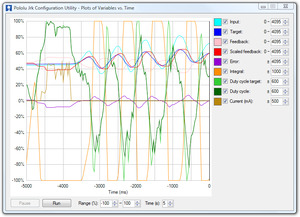

The jrk 12v12 is a versatile, general-purpose motor controller that supports a variety of interfaces, including USB. The 6 V to 16 V operating range and high continuous output current of 12 A (30 A peak) allow this board to control many medium-sized DC brushed motors. Analog voltage and tachometer (frequency) feedback options allow quick implementation of closed-loop servo systems, and a free configuration utility (for Windows) allows easy calibration and configuration through the USB port.

Key improvements over competing products and earlier Pololu motor controllers with feedback include:

|

|

|

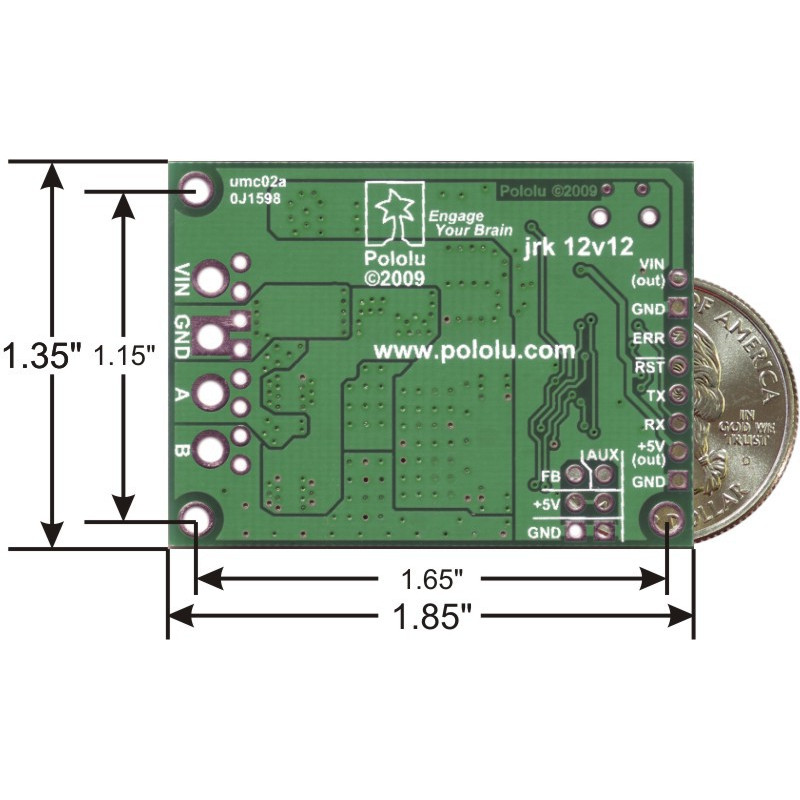

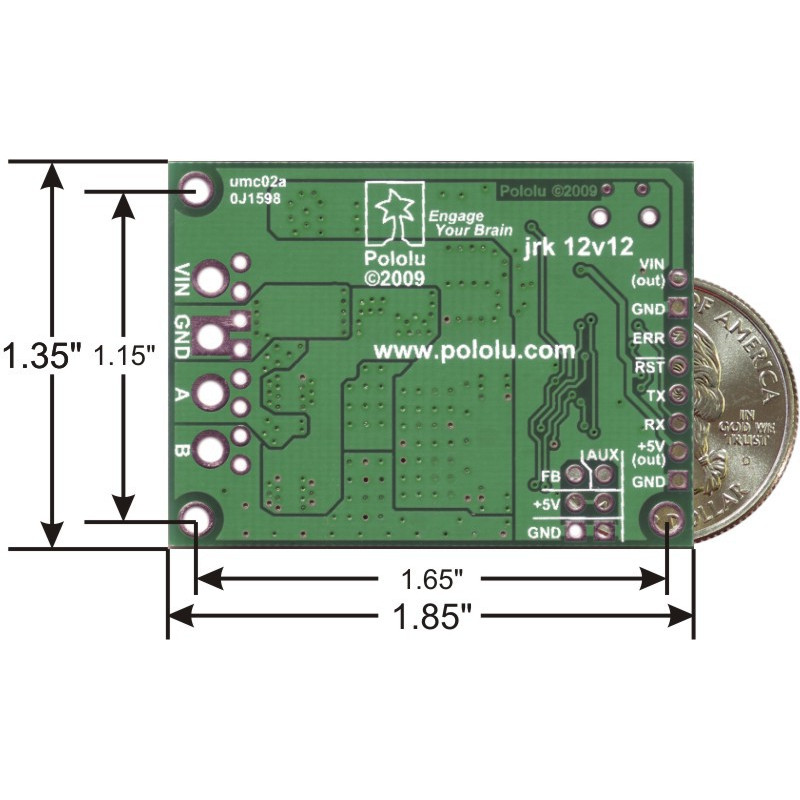

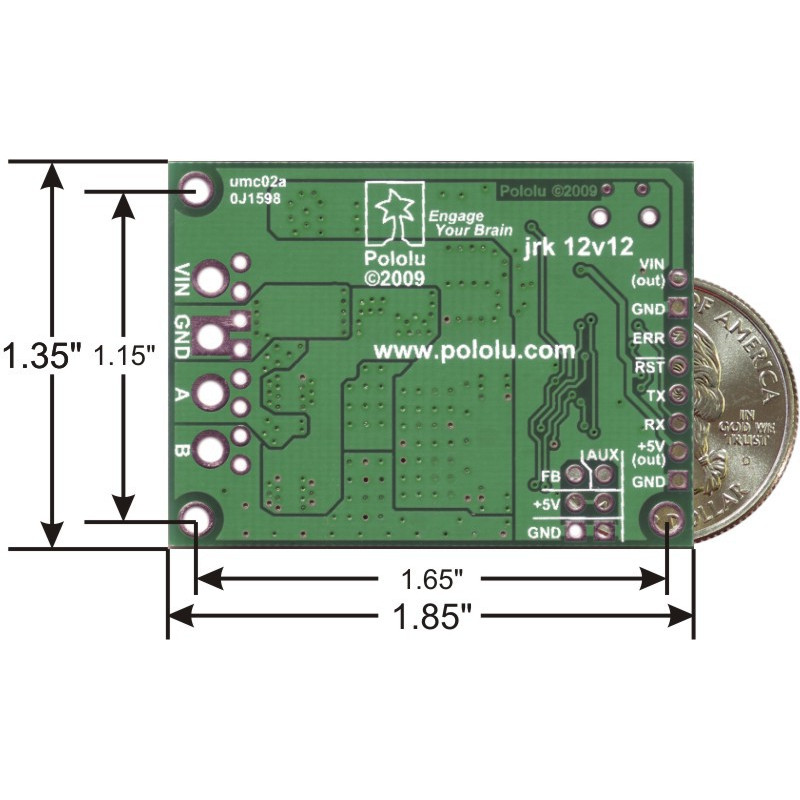

| Motor channels: | 1 |

|---|---|

| Operating voltage: | 6 – 16 V |

| Continuous output current: | 12 A |

| Peak output current: | 30 A |

| Auto-detect baud rate range: | 300 – 115,200 bps |

| Available fixed baud rates: | 300 – 115,200 bps |

| Available PWM frequencies: | 20 kHz, 5 kHz |

| Reverse voltage protection?: | Yes |

| USB connector style: | USB Mini-B |

The jrk 12v12 is the larger of two jrk motor controllers. For a lower-power version that has a wider operating voltage range, see the jrk 21v3.

|

|

|

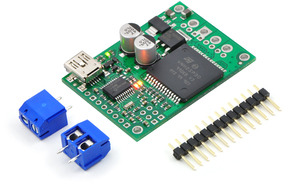

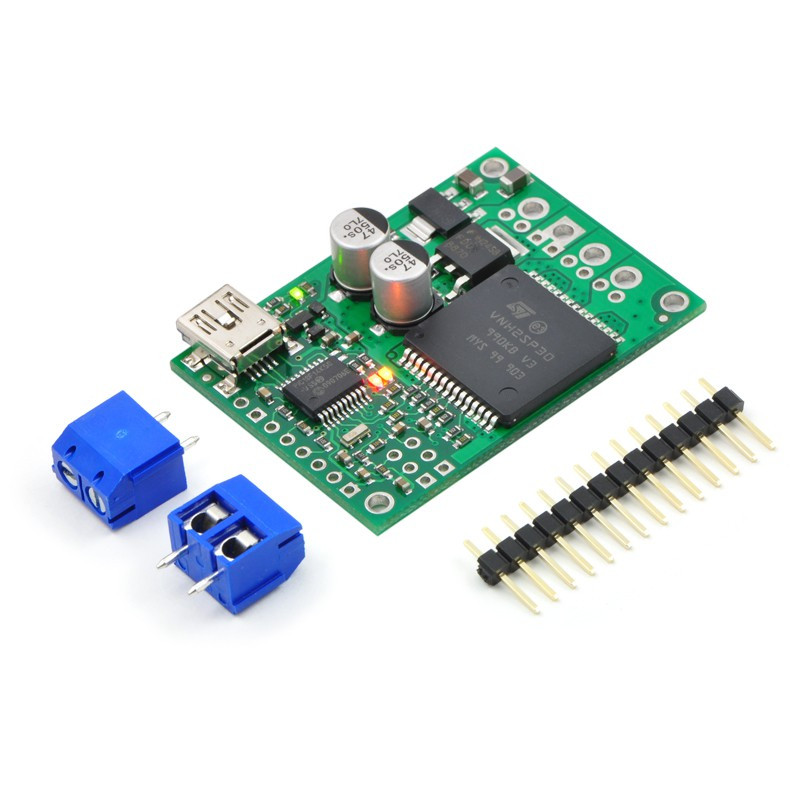

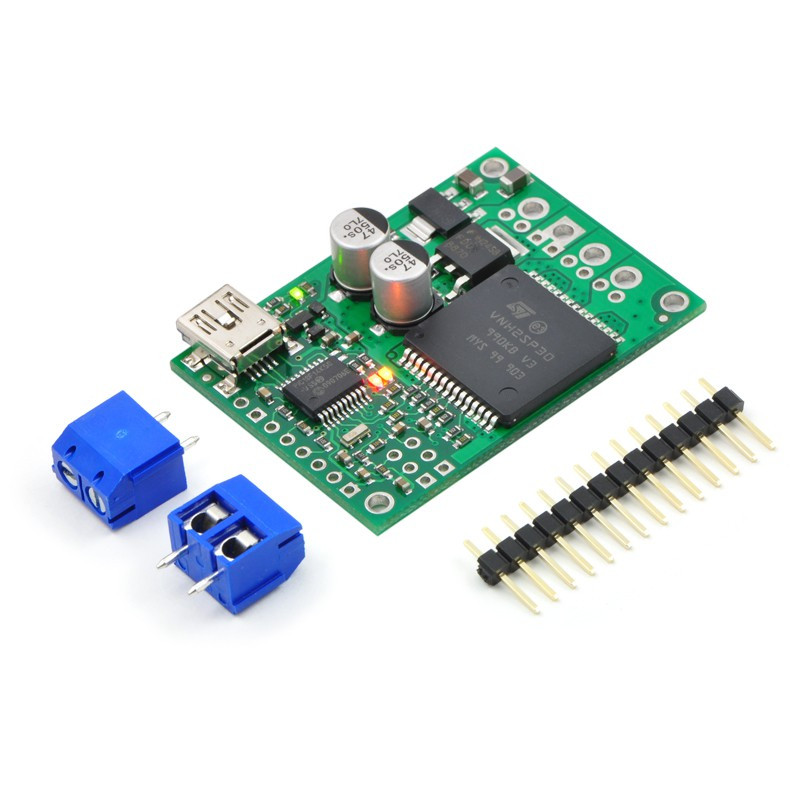

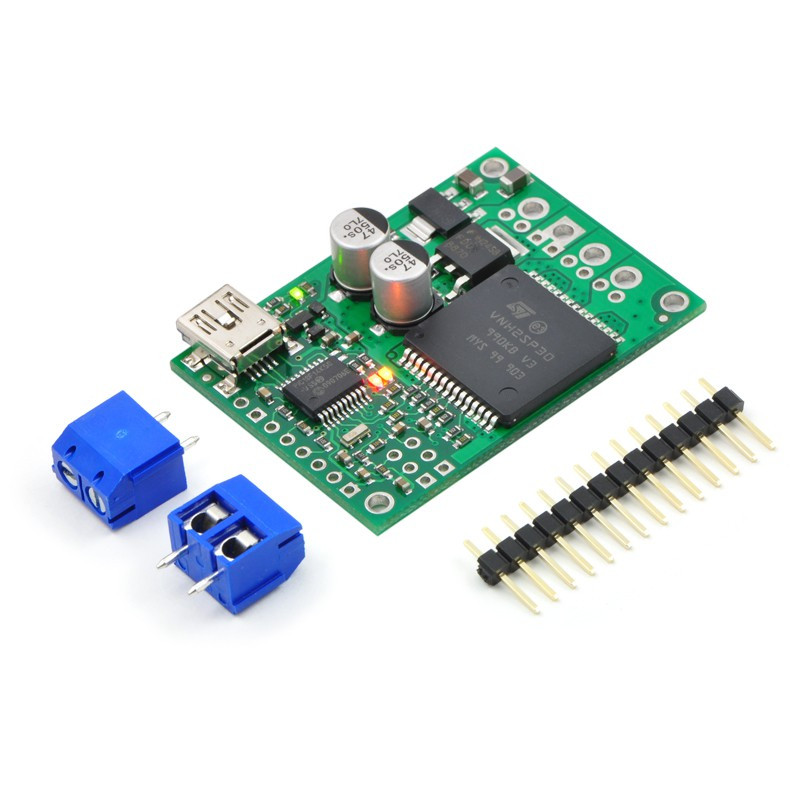

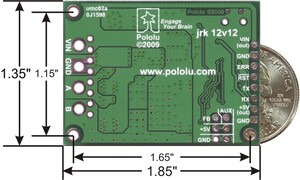

The jrk ships with a straight 0.1″ breakaway male header strip and two 5mm, 2-pin terminal blocks. To provide maximum flexibility, none of these parts are soldered to the board.

For the most compact installation, you can solder wires directly to the jrk pads themselves and skip using the included hardware. The included hardware allows you to make less permanent connections. You can break the header strip into smaller pieces, such as an 8×1 piece and two 3×1 pieces, and solder these strips into the jrk’s I/O pads.

The three mounting holes are intended for use with #2 screws (not included).

Note: A USB A to mini-B cable is not included.

Firmware change notice: The latest firmware version for the jrk 12v12, version 1.4, changes the way the motor is controlled when the duty cycle is set to 0. All jrk 12v12s manufactured after August 24, 2012 ship with this new firmware version. You can tell what version of the firmware you have by running the jrk configuration utility. See the Upgrading Firmware section of the user’s guide for more information.