location_on 4131 Fraser St. Vancouver BC Get Directions

phone 604-875-1993 Call us

access_time Hours

| Monday - Friday | 9AM - 5:30PM |

| Saturday - Sunday & Holidays | Closed | See Holiday Hours |

|

|

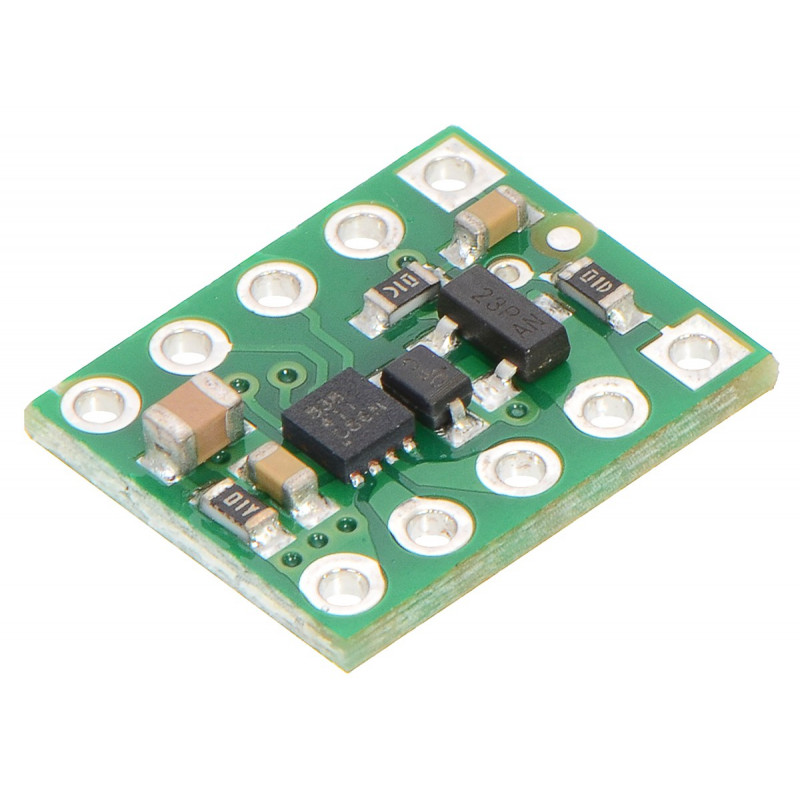

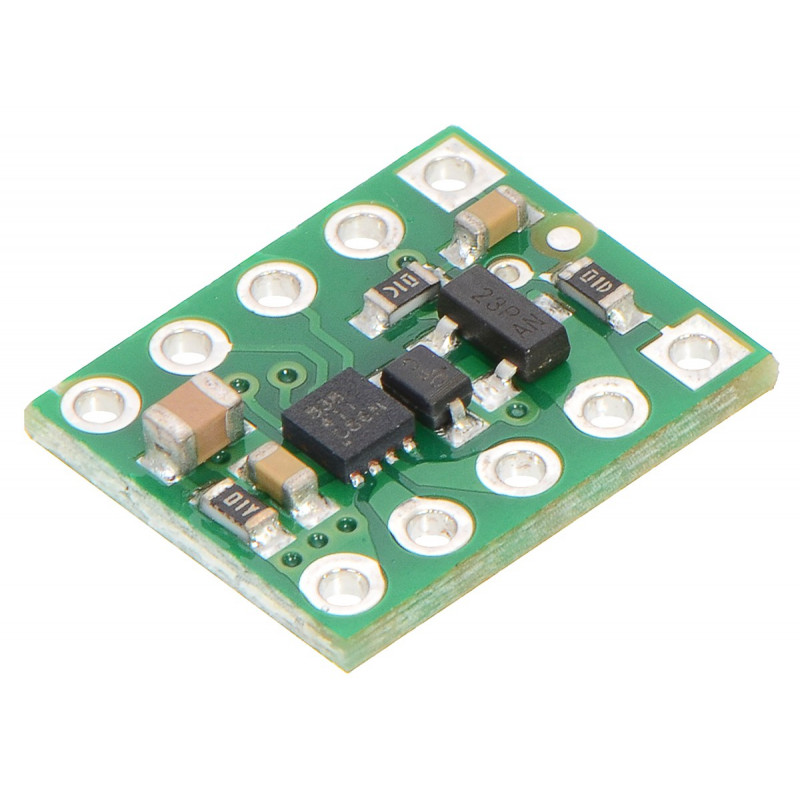

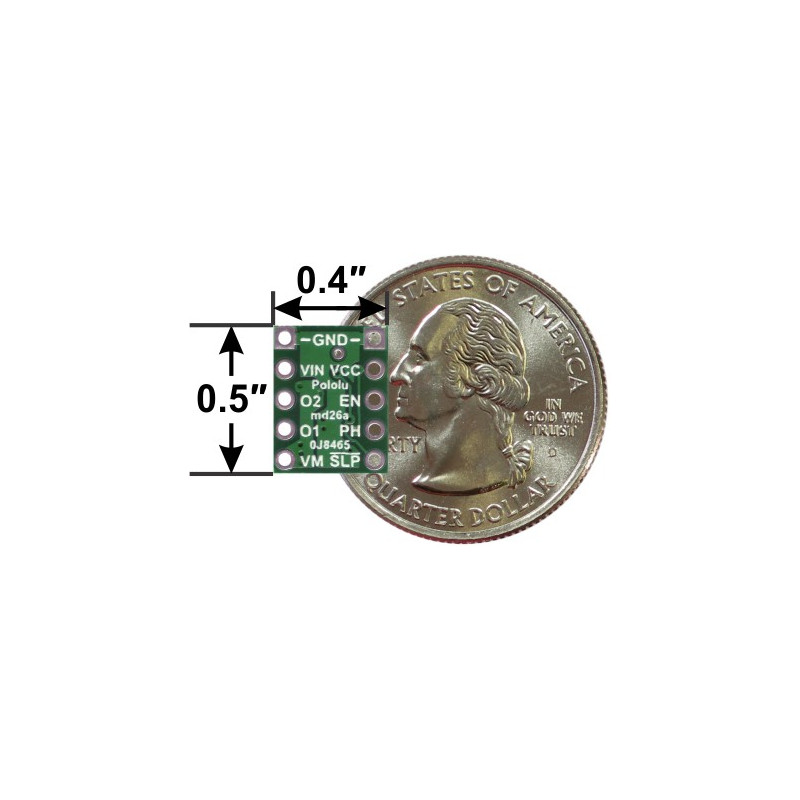

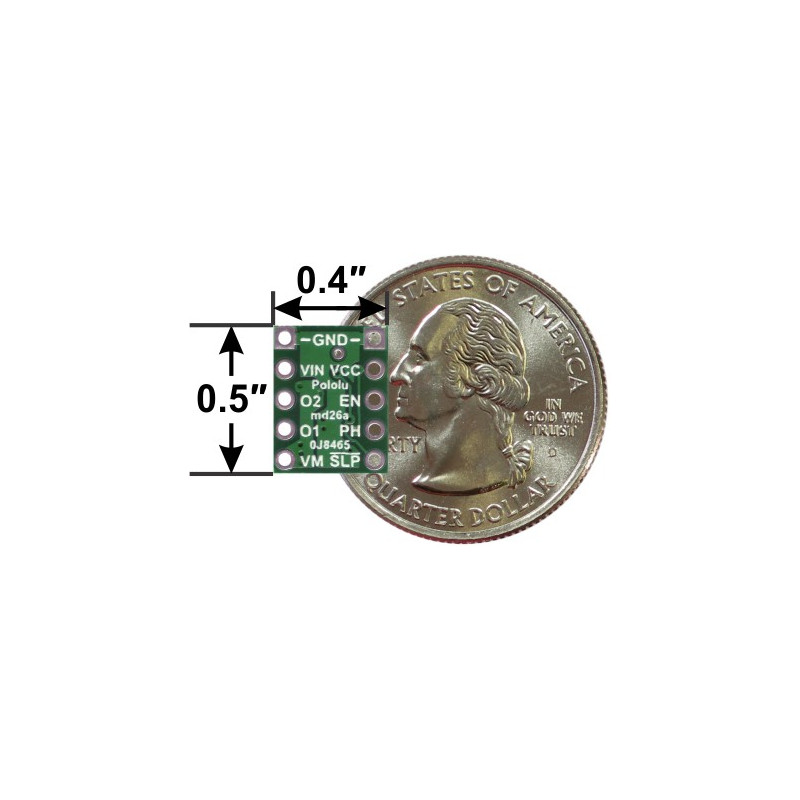

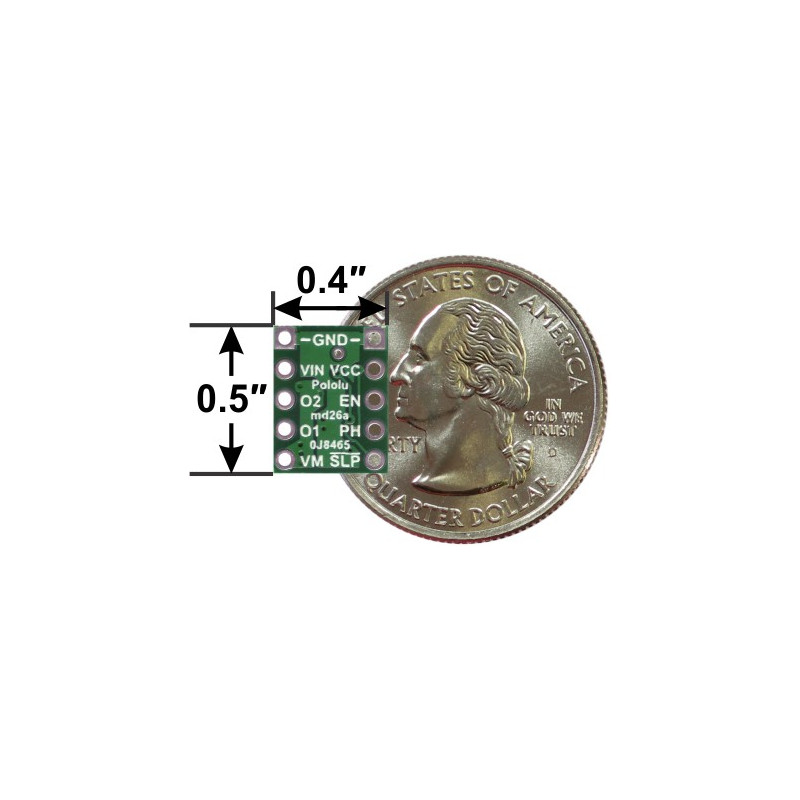

DRV8838 Single Brushed DC Motor Driver Carrier, bottom view with dimensions. |

|---|

|

|

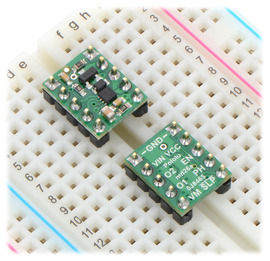

TI SN754410 (16-pin DIP) next to the #2135 DRV8835 carrier (14-pin DIP) and #2990 DRV8838 carrier (10-pin DIP) for size reference. |

|---|

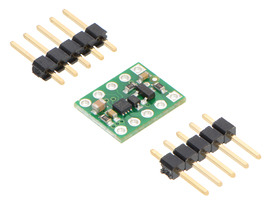

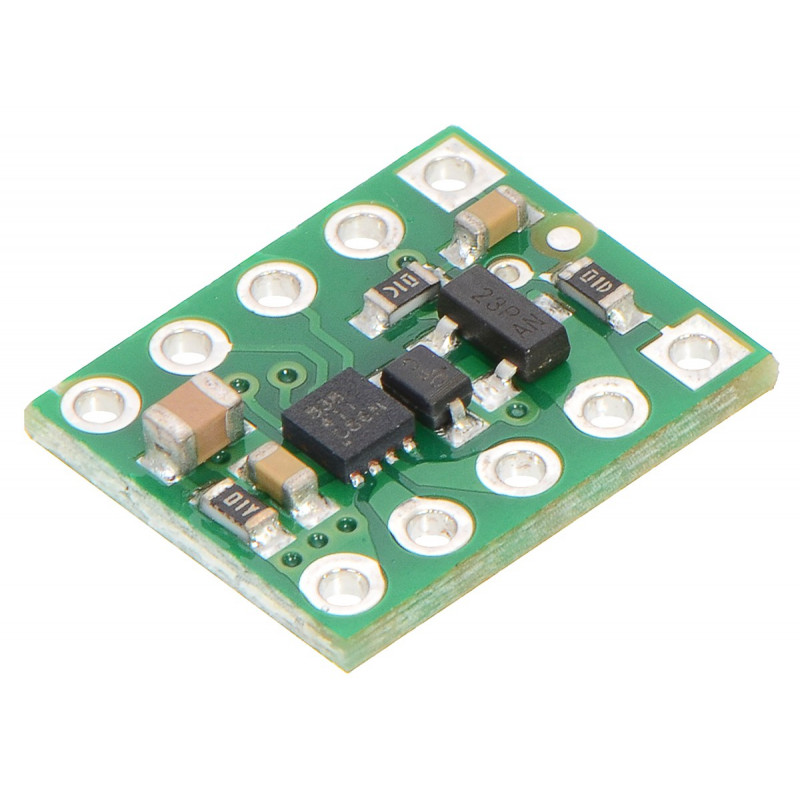

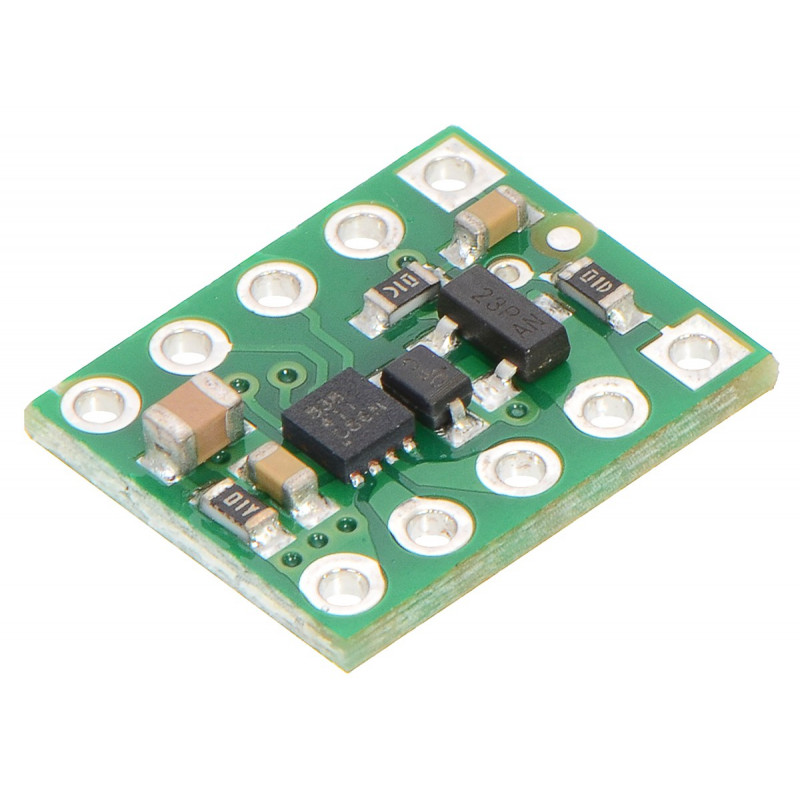

Texas Instruments’ DRV8838 is a tiny H-bridge motor driver IC that can be used for bidirectional control of one brushed DC motor at 0 V to 11 V. It can supply up to about 1.7 A continuously and can tolerate peak currents up to 1.8 A for short durations, making it an ideal driver for small motors that run on low voltages. The DRV8838 is a great IC, but its small, leadless package makes it difficult for the typical student or hobbyist to use; our breakout board gives this driver the form factor of a 10-pin DIP package, which makes it easy to use with standard solderless breadboards and 0.1″ perfboards. Since this board is a carrier for the DRV8838, we recommend careful reading of the DRV8838 datasheet (1MB pdf). The board ships populated with SMD components, including the DRV8838, and adds a FET for reverse battery protection.

This motor driver is essentially a smaller, lower-cost, single-channel alternative to our DRV8835 dual motor driver carrier and DRV8833 dual motor driver carrier, which have very similar operating voltage ranges and current ratings but offer an additional motor channel.

|

|

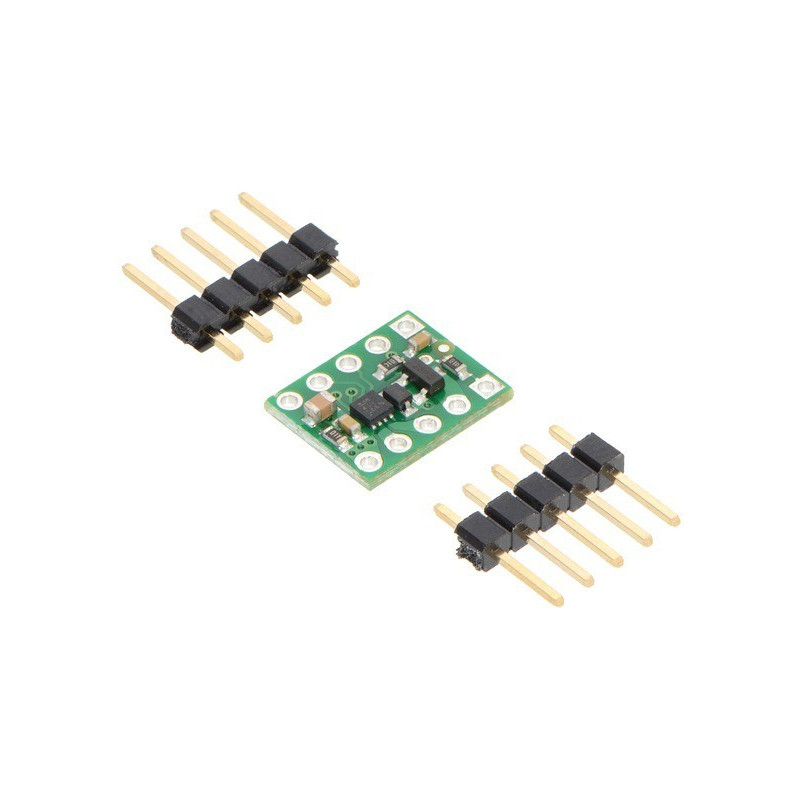

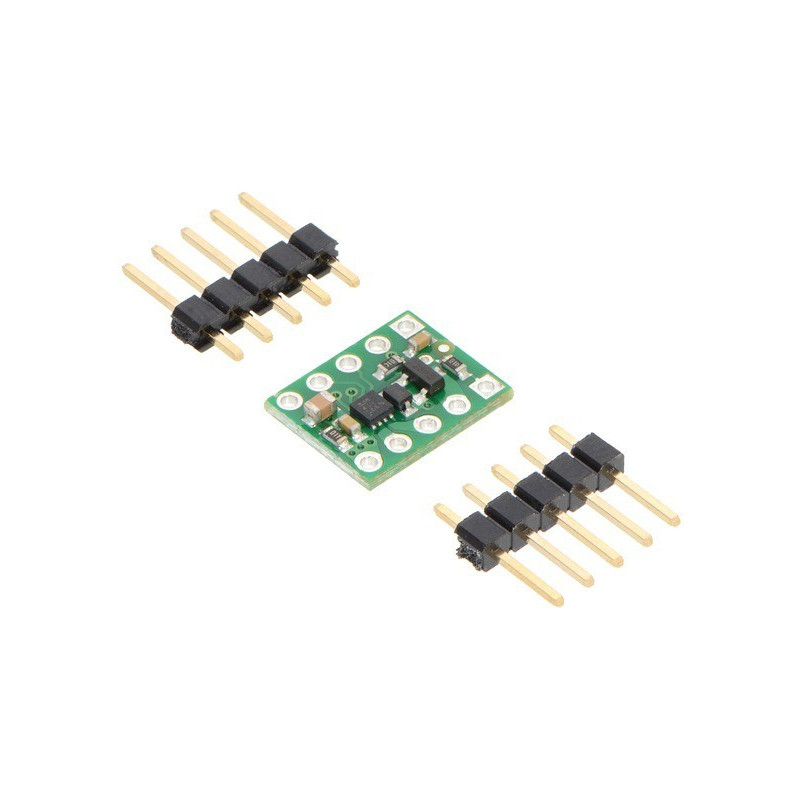

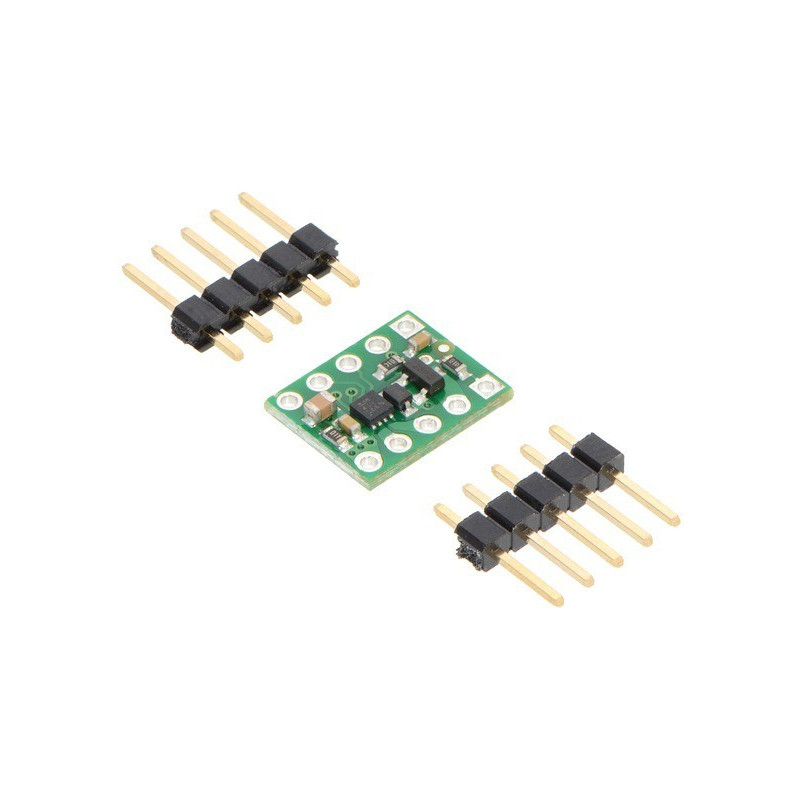

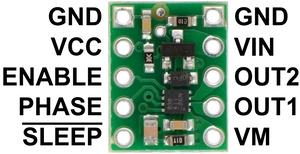

Two 1×5-pin breakaway 0.1″ male headers are included with the DRV8838 motor driver carrier, which can be soldered in to use the driver with breadboards, perfboards, or 0.1″ female connectors. (The headers might ship as a single 1×10 piece that can be broken in half.) The right picture above shows the two possible board orientations when used with these header pins (parts visible or silkscreen visible). You can also solder your motor leads and other connections directly to the board.

|

|

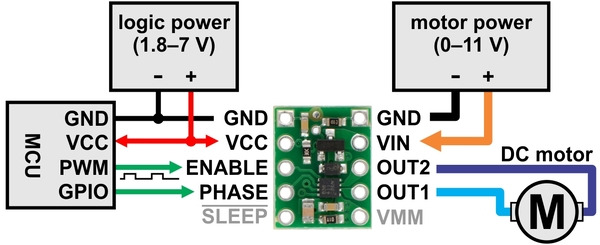

Minimal wiring diagram for connecting a microcontroller to a DRV8838 Single Brushed DC Motor Driver Carrier. |

|---|

Motor and motor power connections are made on one side of the board and logic power and control connections are made on the other. The driver requires a motor voltage between 0 V and 11 V to be supplied to the VIN or VM pin and a logic voltage between 1.8 V and 7 V to be supplied to the VCC pin; the logic voltage can typically be supplied by or shared with the controlling device. The VIN pin is the reverse-protected motor supply input and is the recommended point for connecting motor power. However, driver performance will start getting worse when the input voltage to the reverse-protection circuit is below a few volts, and 1.5 V is the lower limit of where the VIN pin can be used. For very low voltage applications, the motor supply should be connected directly to VM, which bypasses the reverse-protection circuit.

The DRV8838 offers a simple two-pin PHASE/ENABLE control interface, where the PHASE pin determines the motor direction and the ENABLE pin can be supplied with a PWM signal to control the motor speed. The PHASE and ENABLE control inputs are pulled low through weak internal pull-down resistors (approximately 100 kΩ). When the ENABLE pin is low, the motor outputs are both shorted to ground, which results in dynamic braking of a connected motor.

The SLEEP pin can be driven low to put the driver into a low-power sleep mode and turn off the motor outputs, which is useful if you want to let the motor coast. The SLEEP pin is pulled high through a 10 kΩ pull-up resistor on the carrier board so that the driver is awake by default; the quiescent current draw of the board will be dominated by the current through this resistor when the pin is driven low to put the driver to sleep. In most applications, this pin can be left disconnected or can serve primarily as a way to enable coasting. For applications where a low-power sleep mode is desirable, the 10 kΩ pull-up resistor can be removed or the logic voltage (VCC) for the driver can be dynamically supplied by a digital output of your microcontroller.

The following simplified truth table shows how the driver operates:

| PHASE | ENABLE | SLEEP | OUT1 | OUT2 | operating mode |

|---|---|---|---|---|---|

| 0 | PWM | 1 | PWM | L | forward/brake at speed PWM % |

| 1 | PWM | 1 | L | PWM | reverse/brake at speed PWM % |

| X | 0 | 1 | L | L | brake low (outputs shorted to ground) |

| X | X | 0 | Z | Z | coast (outputs floating/disconnected) |

This carrier board can also be used with Texas Instruments’ DRV8837 motor driver IC, which is a pin-compatible alternative to the DRV8838. The DRV8837 has the same functionality and performance as the DRV8838, but it offers a different control interface. The two parts share the same datasheet (1MB pdf), which makes it easy to directly compare the two. If you are looking for a DRV8837 carrier, you can swap out the DRV8838 on one of these boards for a DRV8837 (if you have the appropriate surface-mount rework tools), or we might be able to manufacture a high-volume custom batch for you.

|

| PIN | Default State | Description |

|---|---|---|

| VIN | Reverse-protected motor power supply input. While the driver can operate from a motor supply of 0 V to 11 V, the reverse-protection circuit will start negatively affecting performance below a few volts, and 1.5 V is the lower limit of where it can be used. Power can be supplied directly to VM to bypass the reverse-protection circuit. | |

| VCC | 1.8 V to 7 V logic power supply connection. Logic supply current draw is typically only a few milliamps at most, so in many applications this pin can optionally be dynamically powered by a microcontroller digital output. | |

| VM | This pin gives access to the motor power supply after the reverse-voltage protection MOSFET (see the board schematic below). It can be used to supply reverse-protected power to other components in the system. It is generally intended as an output, but it can also be used to supply board power (such as in cases where the motor supply voltage is too low for the reverse-protection circuit). | |

| GND | Ground connection points for the motor and logic power supplies. The control source and the motor driver must share a common ground. | |

| OUT1 | H-bridge output 1. | |

| OUT2 | H-bridge output 2. | |

| PHASE | LOW | Direction control input. |

| ENABLE | LOW | Speed control input; logic high causes the motor to drive. |

| SLEEP | HIGH | Sleep/coast mode input; logic high results in normal operation. |

The DRV8838 datasheet recommends a maximum continuous current of 1.8 A. However, the chip by itself will typically overheat at lower currents. In our tests, we found that for most combinations of logic (VCC) and motor supply (VIN) voltages, the chip was able to deliver 1.8 A for between 30 seconds and a few minutes before the chip’s thermal protection kicked in and disabled the motor outputs; a continuous current of 1.7 A was sustainable for many minutes without triggering a thermal shutdown.

When both the motor and logic voltages are low (on order of a few volts), the driver will start overheating sooner and the maximum achievable output current will be reduced. For example, in our tests with VIN and VCC at 2 V, the maximum continuous output current of the driver dropped to around 1.4 A, and drawing 1.8 A from the chip caused it to overheat in a few seconds.

The actual current you can deliver will depend on how well you can keep the motor driver cool. The carrier’s printed circuit board is designed to help with this by drawing heat out of the motor driver chip. Our tests were conducted at 100% duty cycle with no forced air flow; PWMing the motor will introduce additional heating proportional to the frequency.

This product can get hot enough to burn you long before the chip overheats. Take care when handling this product and other components connected to it.

|

|

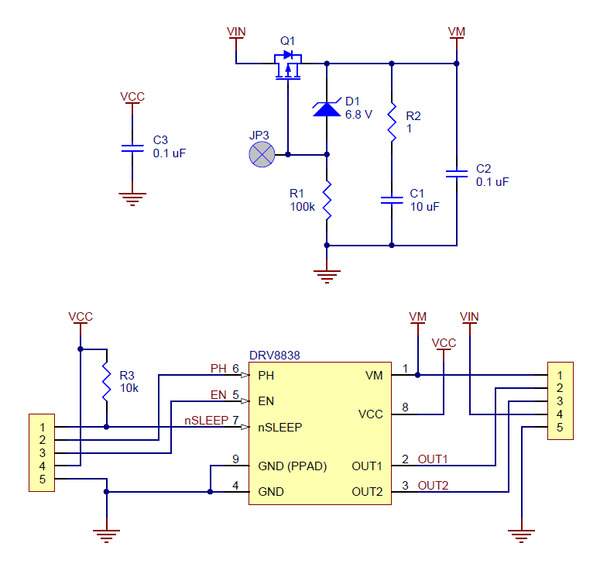

DRV8838 Single Brushed DC Motor Driver Carrier schematic diagram.

|

|---|