location_on 4131 Fraser St. Vancouver BC Get Directions

phone 604-875-1993 Call us

access_time Hours

| Monday - Friday | 9AM - 5:30PM |

| Saturday - Sunday & Holidays | Closed | See Holiday Hours |

This item has been retired.

Material Grade: NatureWorks 4032D

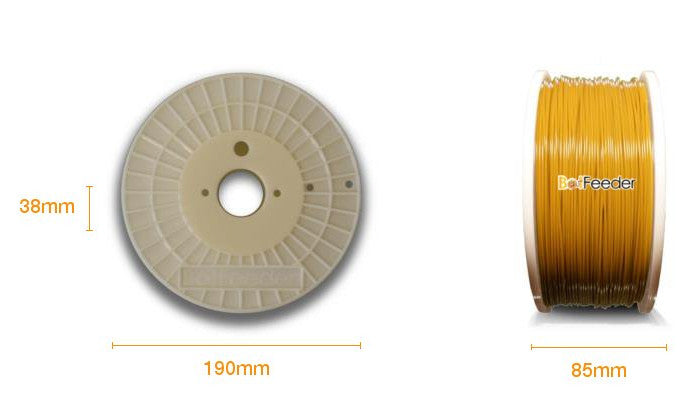

Diameter Tolerance: +/- 0.03mm

Roundness Tolerance: +/- 0.05mm

At BotFeeder we have a well equipped 3d printing studio with a lot of popular 3D printers. We know our materials will give you excellent results and to help you get these results here are tips and trick for using BotFeeder 3D printing filament.

Extrusion Temperature: 200 to 220C

3D print speed: 15 to 100 mm/sec

Print Bed Temperature: 65 to 70C (Optional)

Layer Thickness: 0.05mm or higher

Nozzle Size: 0.1mm or higher

Build Platform: For BotFeeder PLA we advice to print on a heated bed. After printing, the build plate needs to cool down to about 20-30 C at which point you can remove the printed part.

![]()

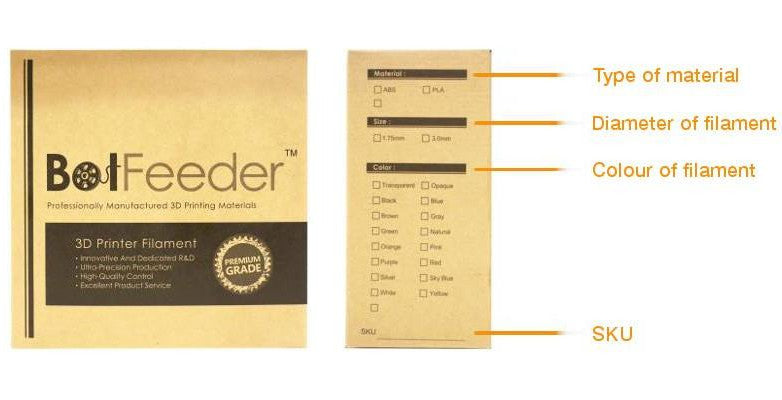

To ensure the filament product to your hand is in its top condition, we're taking extra protective measures, including protective film, heavy-duty vacuum seal bag, double air-tight seal, and large pack of desiccant.

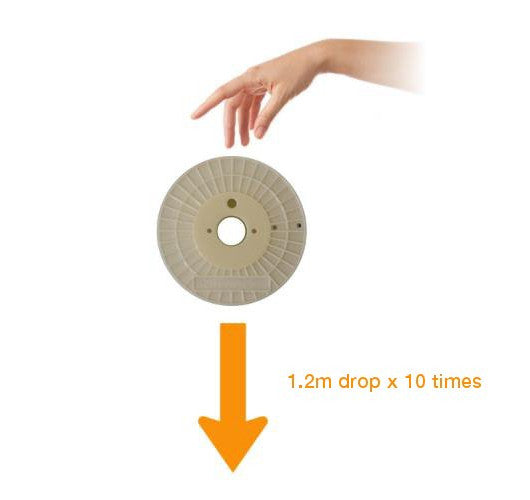

Method: 10 drops from height of 1.2 meters

Result: Passed

Product: PLA 1.75mm Caramel Filament

SKU: 3510

1 x 1kg of BotFeeder PLA 1.75mm Caramel Filament

1 x BotFeeder spool holder

1 x A pack of large desiccant

1 x Vacuumed sealed bag

Please note that improper storage may damage your filament. To maintain its original quality, it's strongly recommended that the filament be stored in the following conditions:

- a dehumidifier cabinet or a dry and circulated area

- room temperature

- avoid direct sunlight or heat source

Please note poor printer location will have a negative effect on your print result and possible of damaging your filament. To select the most ideal location for your printer, please follow this guide.

- Avoid direct sunlight or heat source

- Consistent temperature

- Stable air flow

- Away from furniture for safety

When unpacking, changing filament or unloading, It is strongly suggested to get a good grip at the end of the filament at all times in order to prevent tangling. The spool holder is specifically designed with 2 holes of each side, allowing you to secure the end of the filament by threading into it. or you can simply 3D print a "Filament clip" that is attached to the spool holder itself.

Dry it slowly in room temperature. Please note that heat drying the filament will damages its quality by making it become brittle. The preferred method of drying your filament is to put in a dehumidifier cabinet or in an airtight bag with a few packs of desiccants. It's recommended to maintain a humidity level of 25% or less.

All BotFeeder 3d printing filaments are produced in our own production facility, situated in the Taiwan. Since no external parties are involved in the making of BotFeeder filament we can ensure consistent quality on every order.

An important machine in our production are the laser measurement systems used to check the diameter of our filament real time during production. It’s measured over 1000 times per second and helps us guarantee that each spool of BotFeeder 3d printing filament produced within tolerance. We can guarantee 0.03mm +/- on both 2.90mm and 1.75mm BotFeeder 3d printing filament, which means you can rest assured that your printer is extruding the exact amount of material.

Within minutes of production a spool of BotFeeder 3d printing filament is sealed airtight with a double barrier foil. To go the extra mile, we’ll also seal the fancy cardboard box that we use to ship our product. You can make sure BotFeeder 3d printing filament is fresh and ready for 3d printing when you’re done unboxing.

The BotFeeder testlab features a wide range of popular 3d printers. We’re continuously testing on our 3d printers to keep checking the quality of the materials we produce and to develop exciting new materials for the maker community. If your not sure how to print with our materials on your 3d printer, please contact us at [email protected]

Ultimaker Original

Ultimaker 2

Makerbot Replicator 2X

Lulzbot Mini

Original Pursa I3

Solidoodle 3

UFO Standard (Delta & E3D hot-end)

Rapidbot 2

3D Lounge PRO XL

Companies who are interested in having their 3d printer(s) featured in our testlab can contact us at [email protected]

To take an extra step for your safety, BotFeeder 3d printing filaments are being tested on an annually basis by SGS. On top of that, all our filaments are manufactured in compliance of RoHS (Restriction of Hazardous Substances).

BotFeeder was founded as a brand of Liing Shian Colorant Manufacturer which have been active in the masterbatch, and pigment & chemical auxiliaries for the plastics processing industry. Our knowhow, network and partnerships is driving material innovations and quality. You can expect BotFeeder to keep on developing interesting new materials, which will be tested on a variety of printers to make sure it’ll get the job done.